边缘缺角

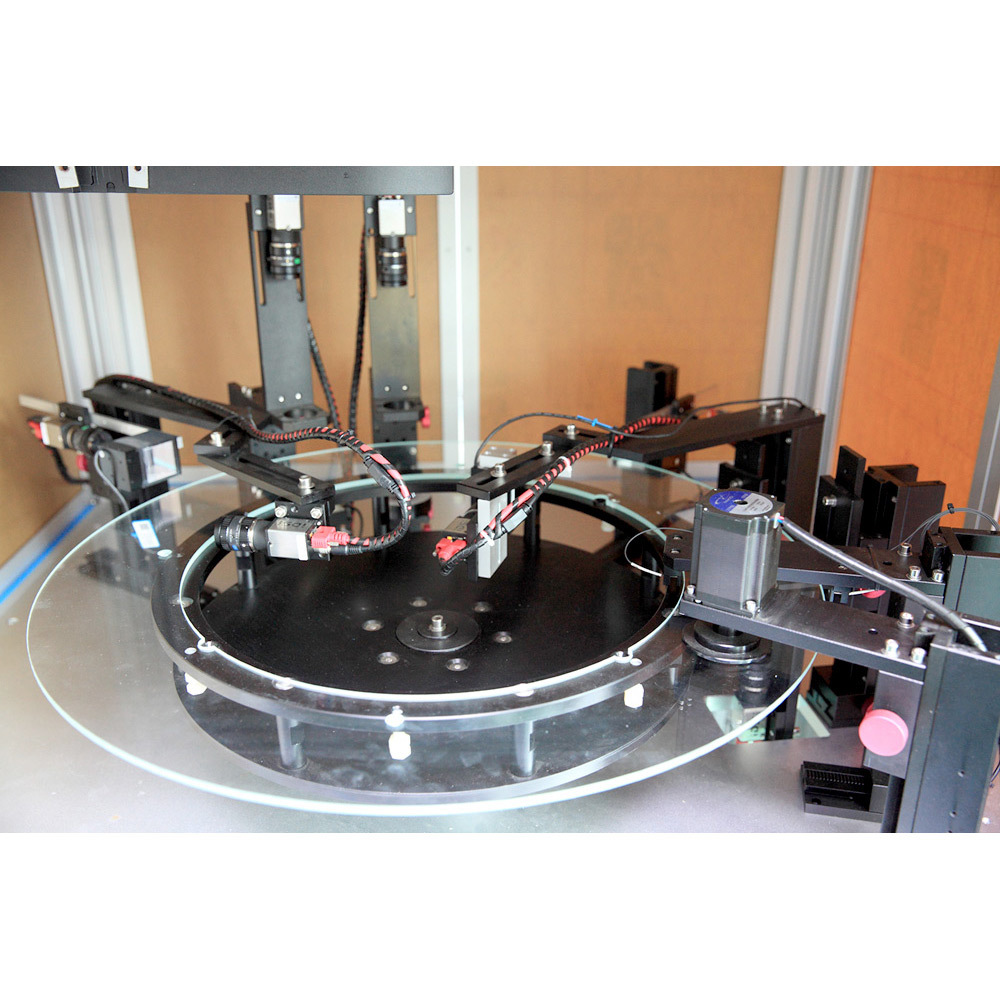

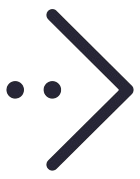

Magnetic Tile Optical Sorting Machine

Inspection items: ● Crack and scratch detection ● Edge and corner chipping detection ● Bump and material excess detection ● Size detection ● Material shortage detection

Key words:

CCD optical sorting system for magnetic materials china

Filterable Objects

Filterable Features

Product Detail

|

Parameters:

Detection efficiency:

Product detection range:

Detection method:

|

|

Inspection items: ● Crack and scratch detection ● Edge and corner chipping detection ● Bump and material excess detection ● Size detection ● Material shortage detection |

|

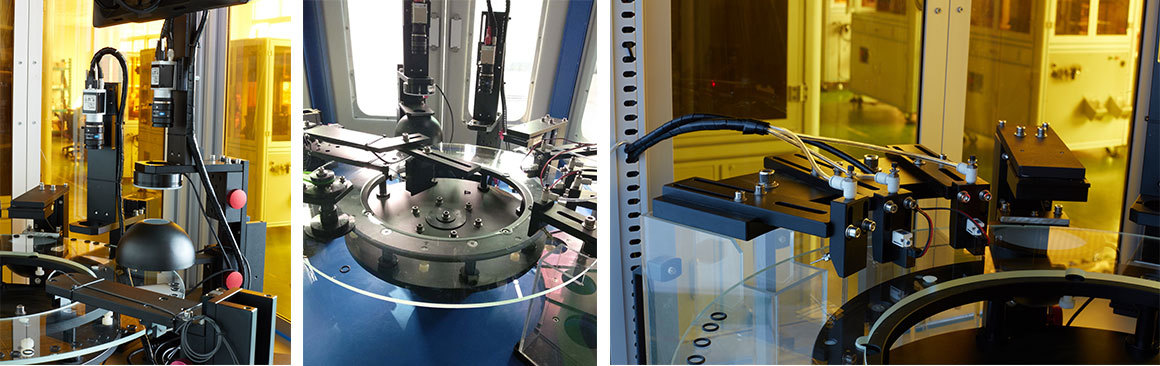

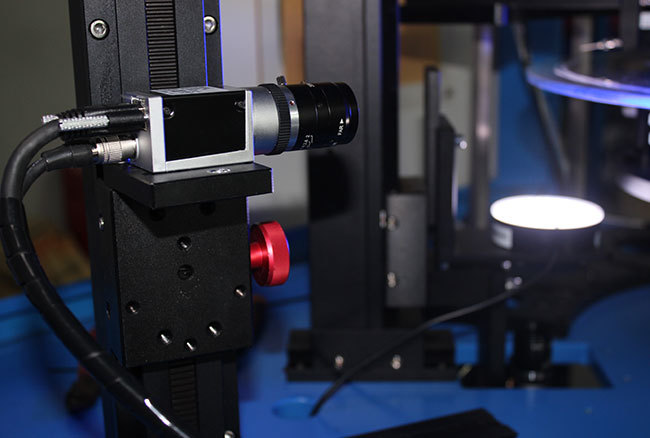

At the heart of the Magnetic Tile Optical Sorting Machine lies its sophisticated optical inspection system, which leverages high-resolution cameras, multi-spectral imaging, and advanced algorithms to analyze every inch of a magnetic tile’s surface and structure. Unlike traditional manual sorting or basic mechanical systems, this machine can detect even the most minute imperfections: micro-cracks, surface scratches, uneven magnetism distribution, and dimensional deviations as small as a few micrometers. This level of precision is indispensable in industries such as automotive and aerospace, where magnetic tiles must meet strict performance and safety criteria.

The Magnetic Tile Optical Sorting Machine can be easily calibrated to handle different specifications, thanks to its user-friendly interface and customizable inspection parameters. Whether sorting ferrite tiles for household appliances or rare-earth magnetic tiles for high-performance motors, the machine adjusts seamlessly, ensuring consistent quality across diverse product lines.

Durability and reliability are also hallmarks of the Magnetic Tile Optical Sorting Machine. Built with robust materials and designed to withstand the rigors of continuous industrial use, it requires minimal maintenance, ensuring uninterrupted operation even in high-volume production environments. Its advanced dust and vibration resistance features further extend its lifespan, making it a long-term investment that delivers consistent returns.

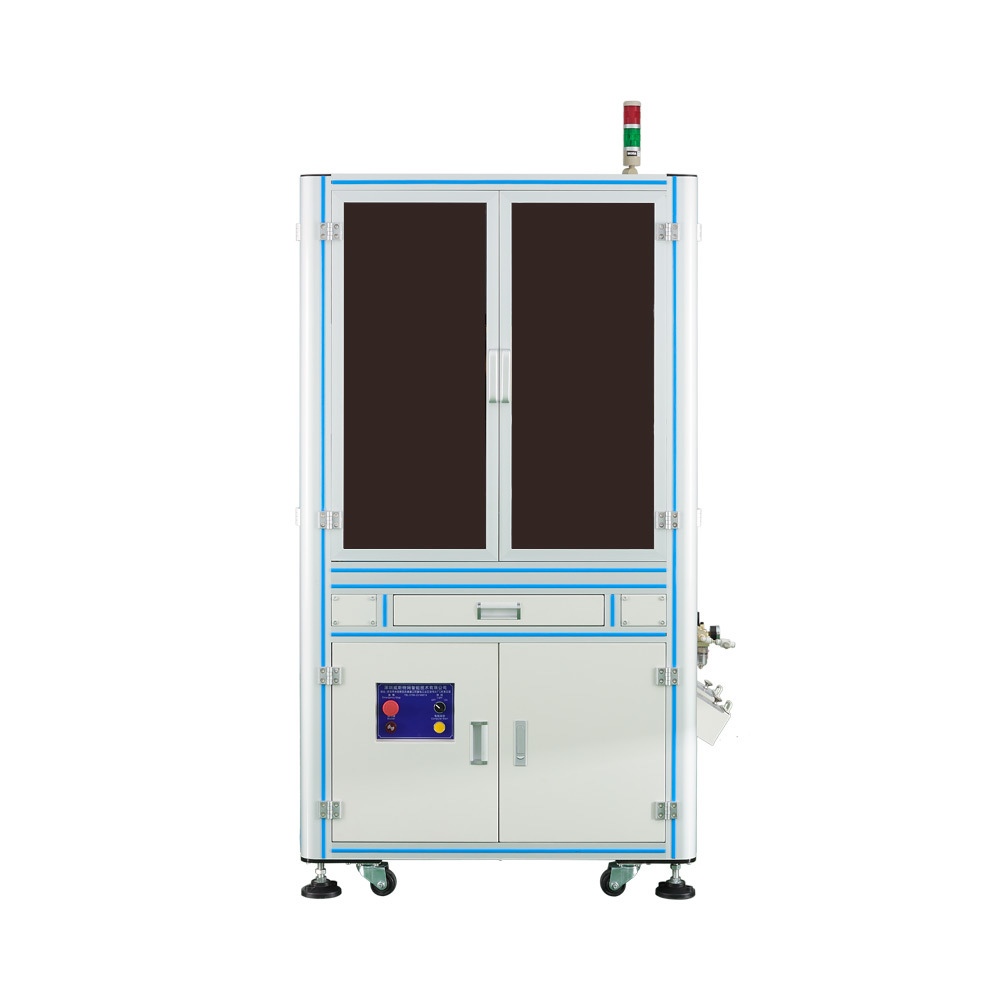

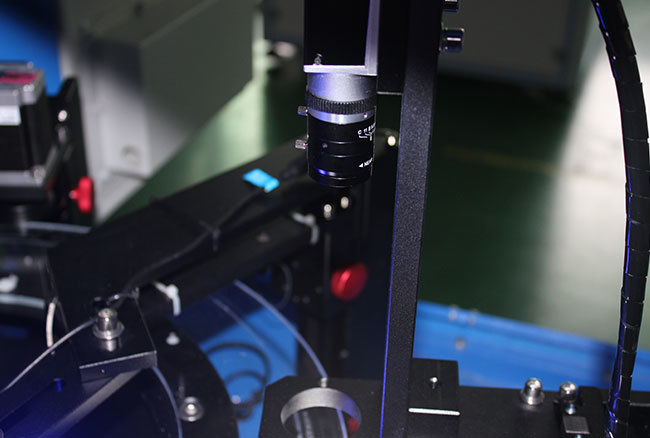

Equipment Internal Display

Camera Multi-Angle Illumination

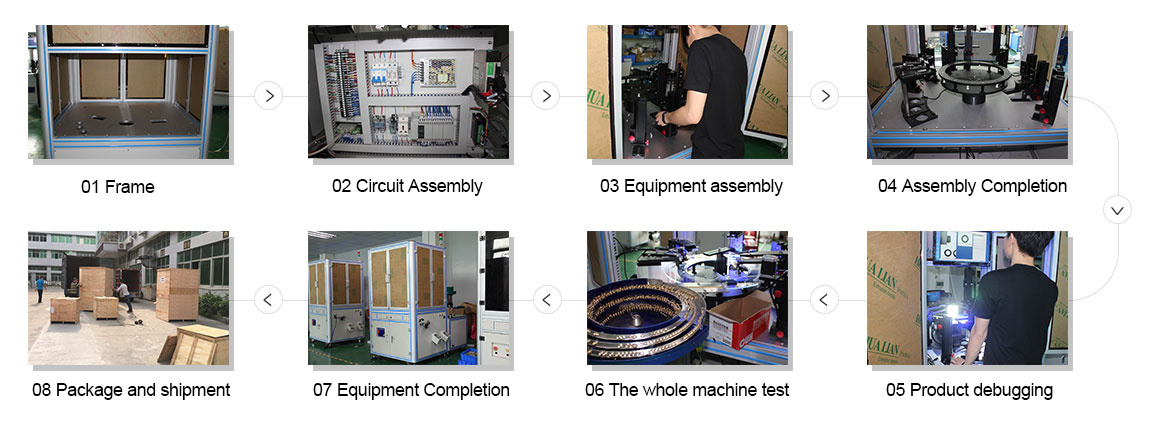

Production Process

Factory Description

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your inquiry and we will come back to you as soon as possible.

Video Display

Application Description

We can provide customized automated testing solutions for products in different industries. Our main products include CCD glass disc screening machines, CCD indexing disc screening machines, CCD 360 degree rotating screening machines, and fully automatic contact detection machines.

Why Choose Us?

01

The products can be made completely according to the customer's requirements

02

High quality product and good price.

03

Good Pre-sale、on sale and after sales service.

04

Short delivery time, Exported all over the world, with rich experience.

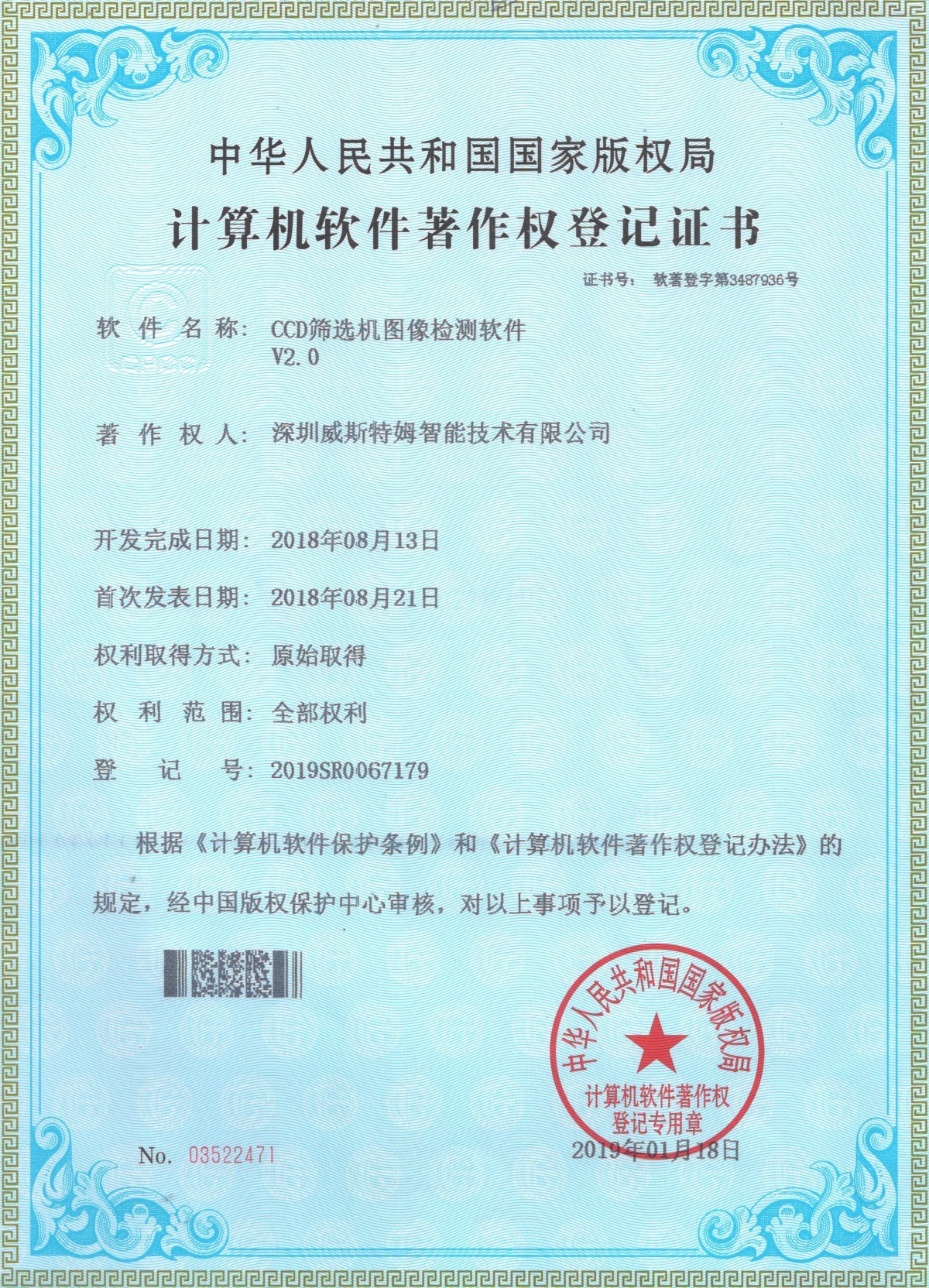

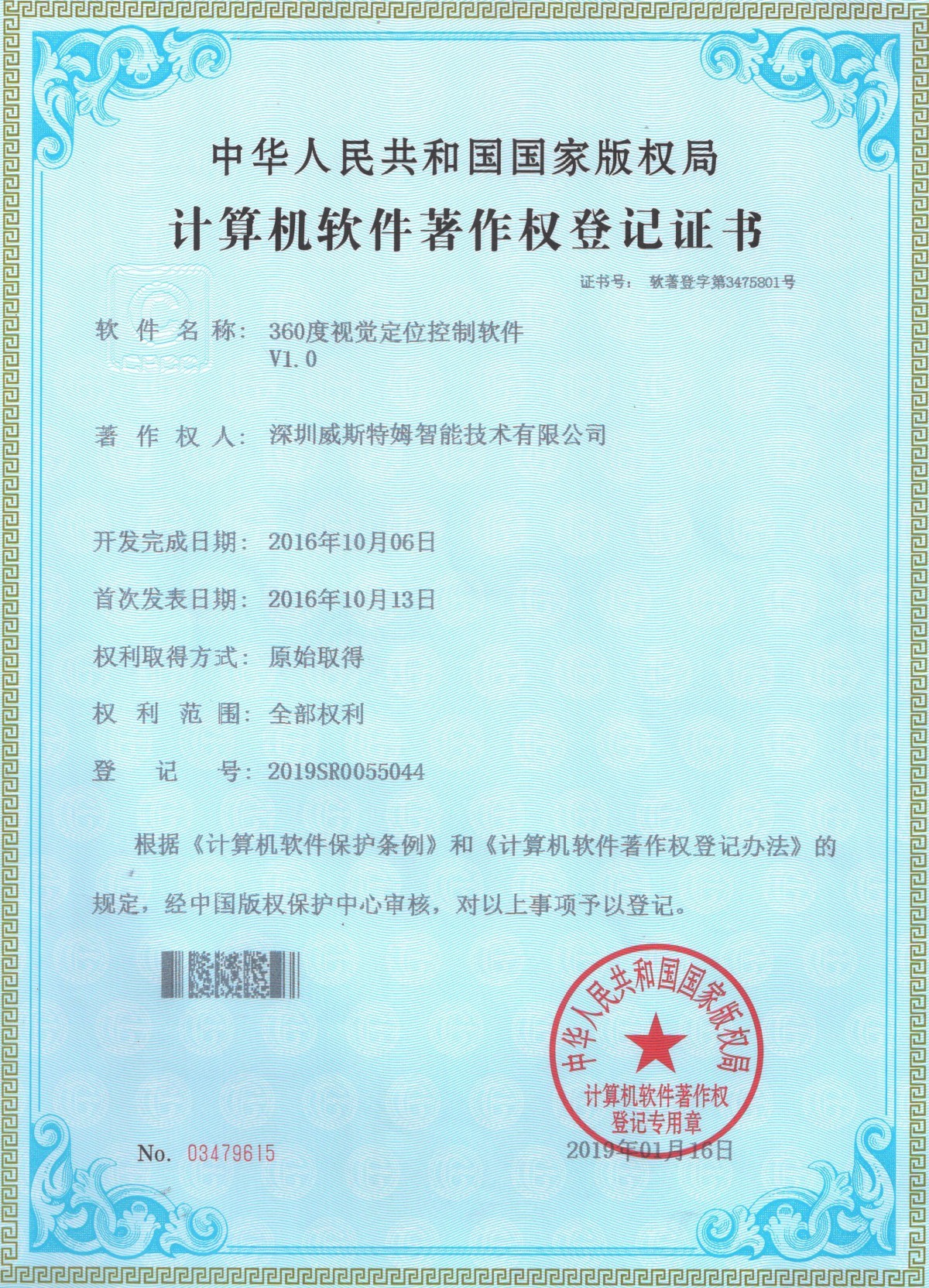

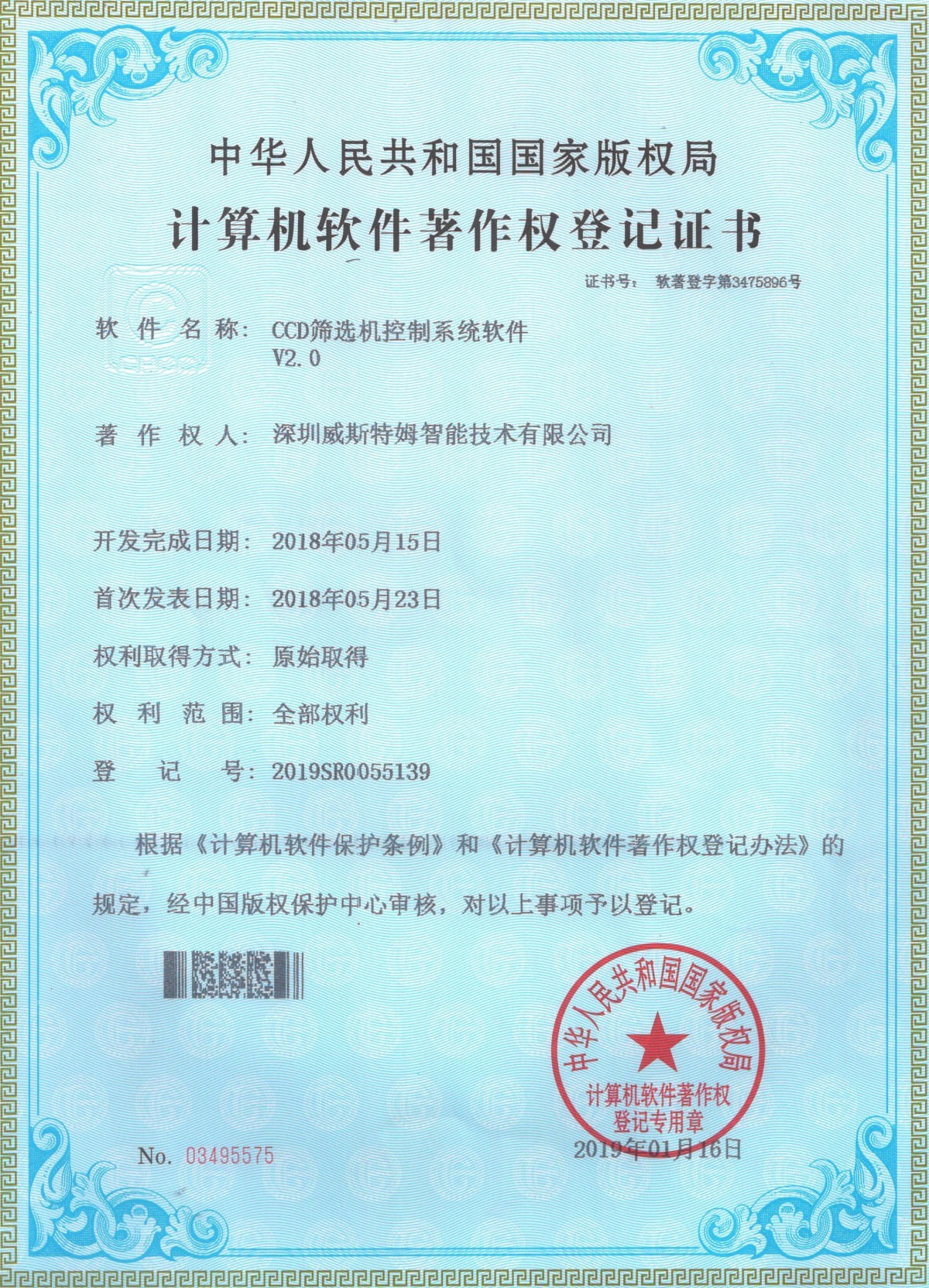

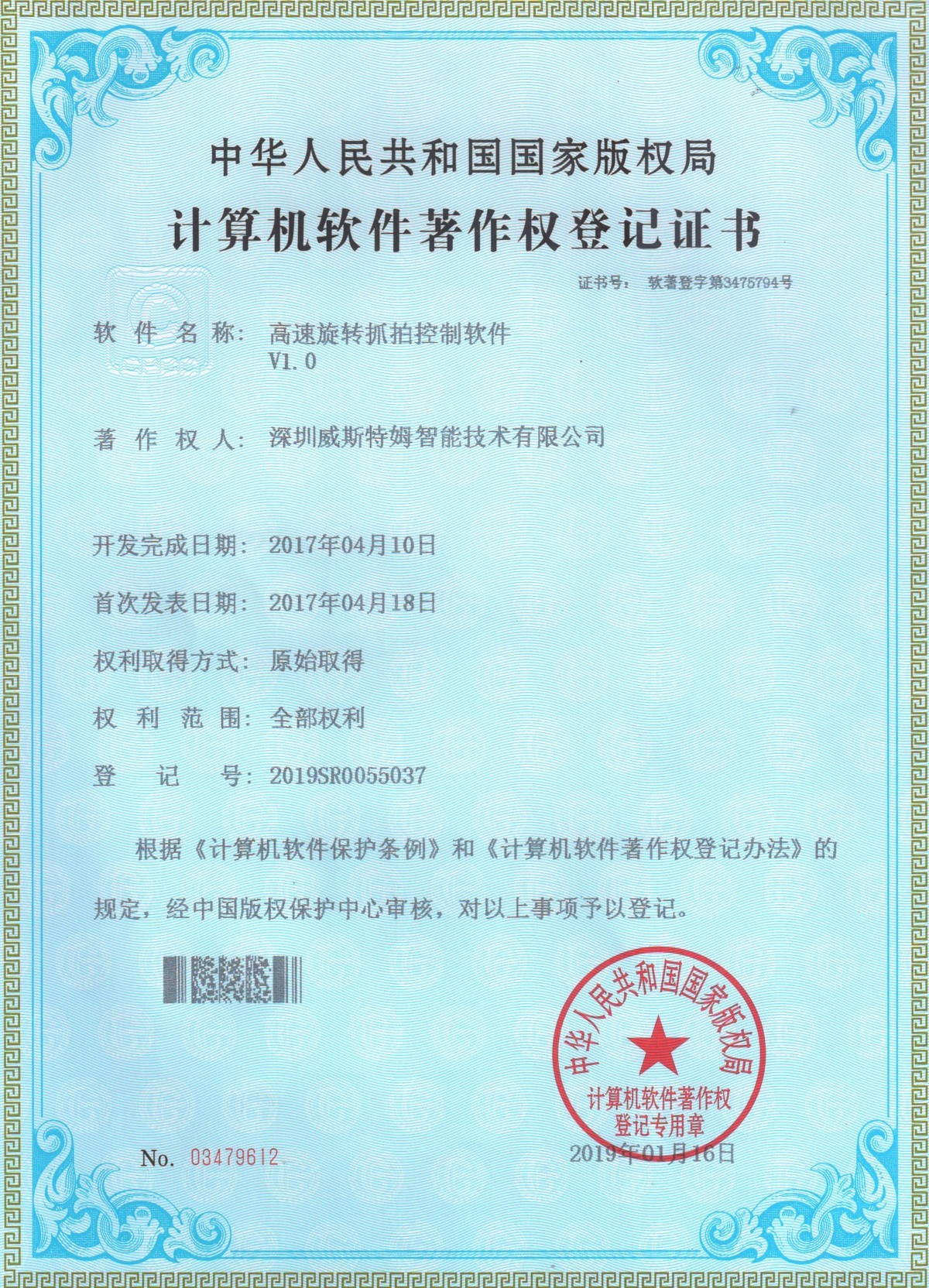

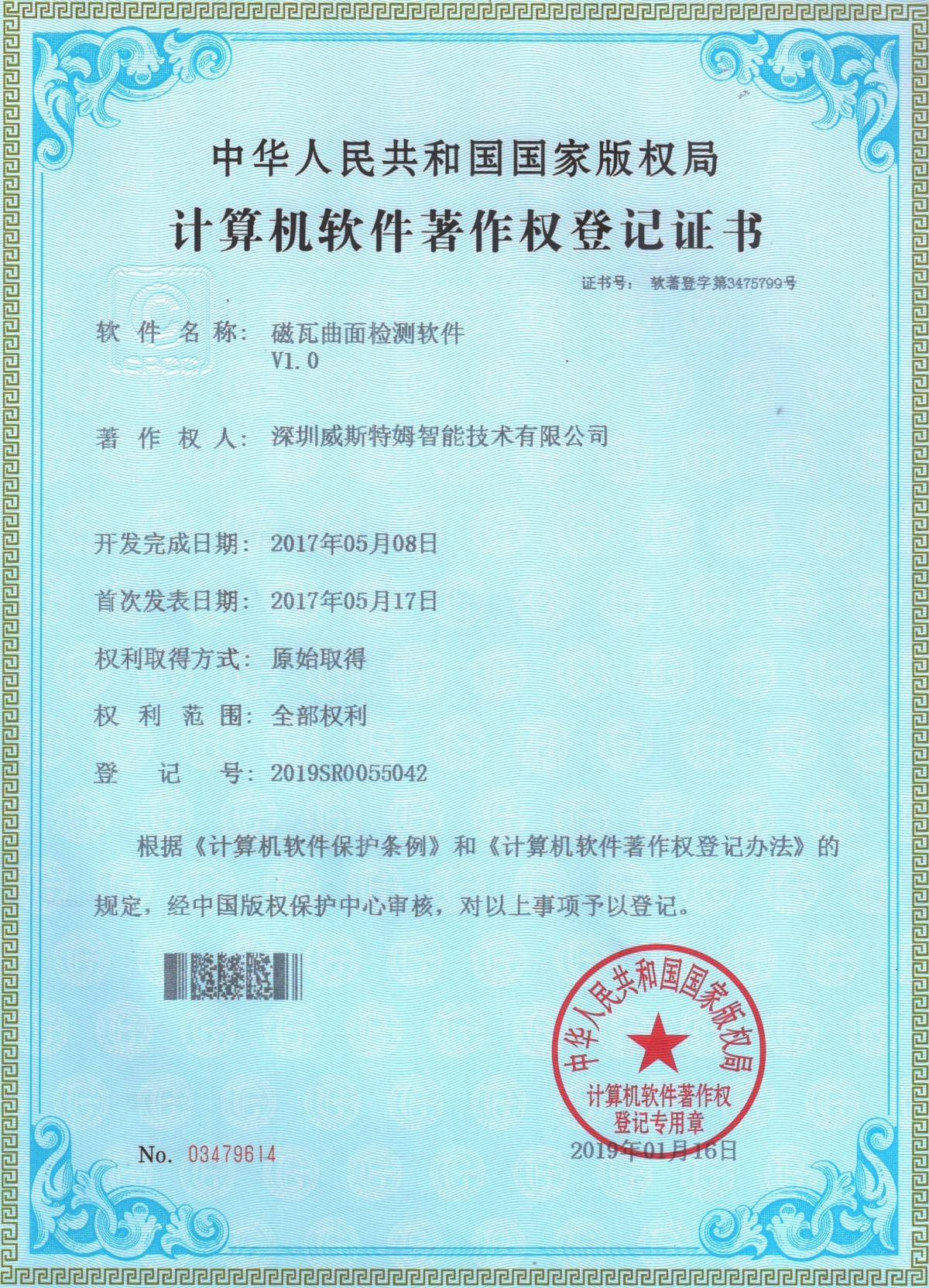

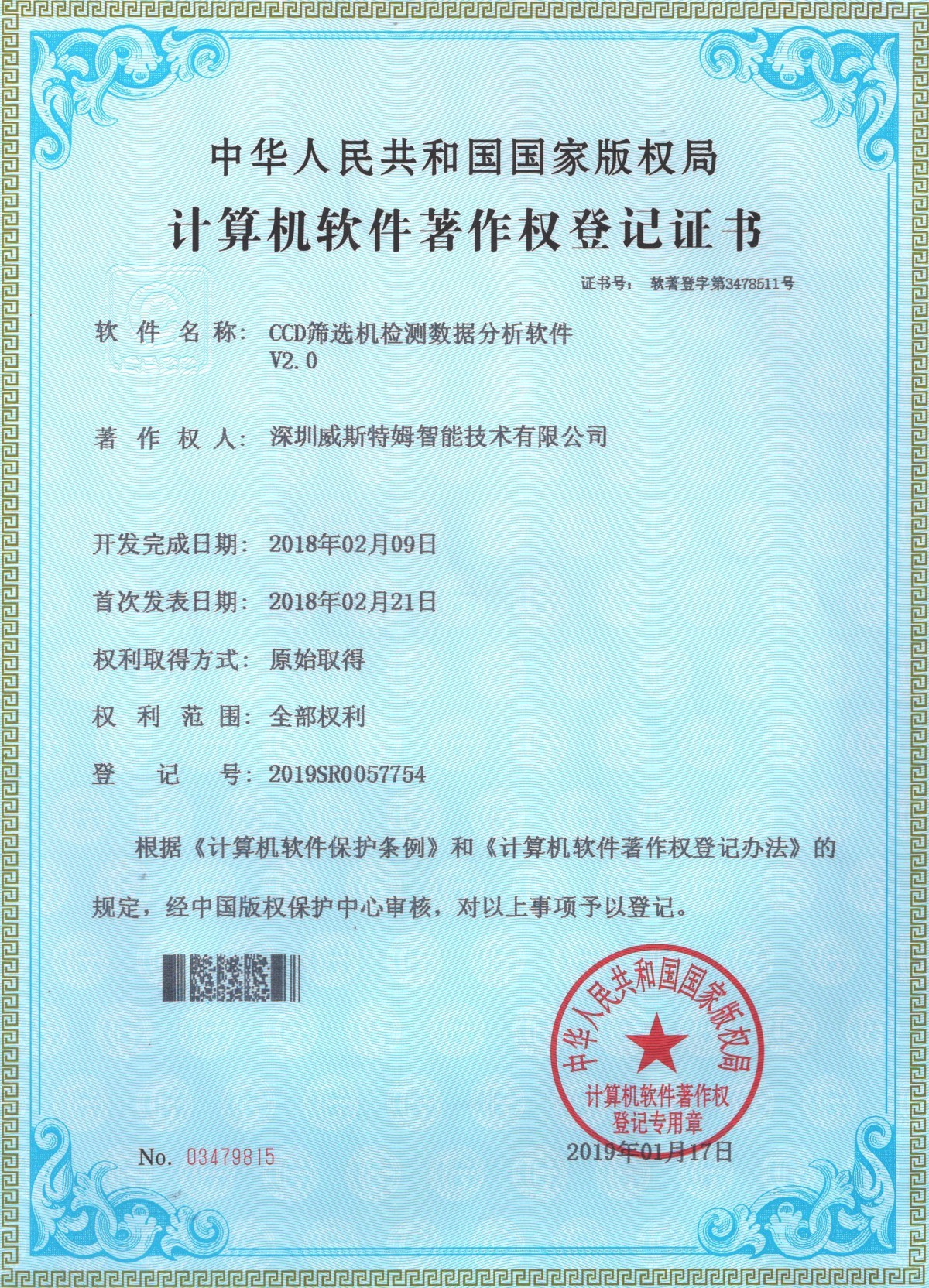

Certificate