Maximizing Efficiency with CCD360 Degree Rotating Screening Machines: A Comprehensive Guide

Maximizing Efficiency with CCD360 Degree Rotating Screening Machines

Table of Contents

- 1. Introduction to CCD360 Degree Rotating Screening Machines

- 2. Understanding Screening Technology

- 3. Benefits of CCD360 Degree Rotating Screening Technology

- 4. Technical Specifications of CCD360 Machines

- 5. Operational Principles of CCD360 Screening Machines

- 6. Implementation Strategies for CCD360 Machines

- 7. Maintenance Tips for Longevity

- 8. Future Trends in Screening Technology

- 9. Conclusion

- 10. Frequently Asked Questions (FAQs)

1. Introduction to CCD360 Degree Rotating Screening Machines

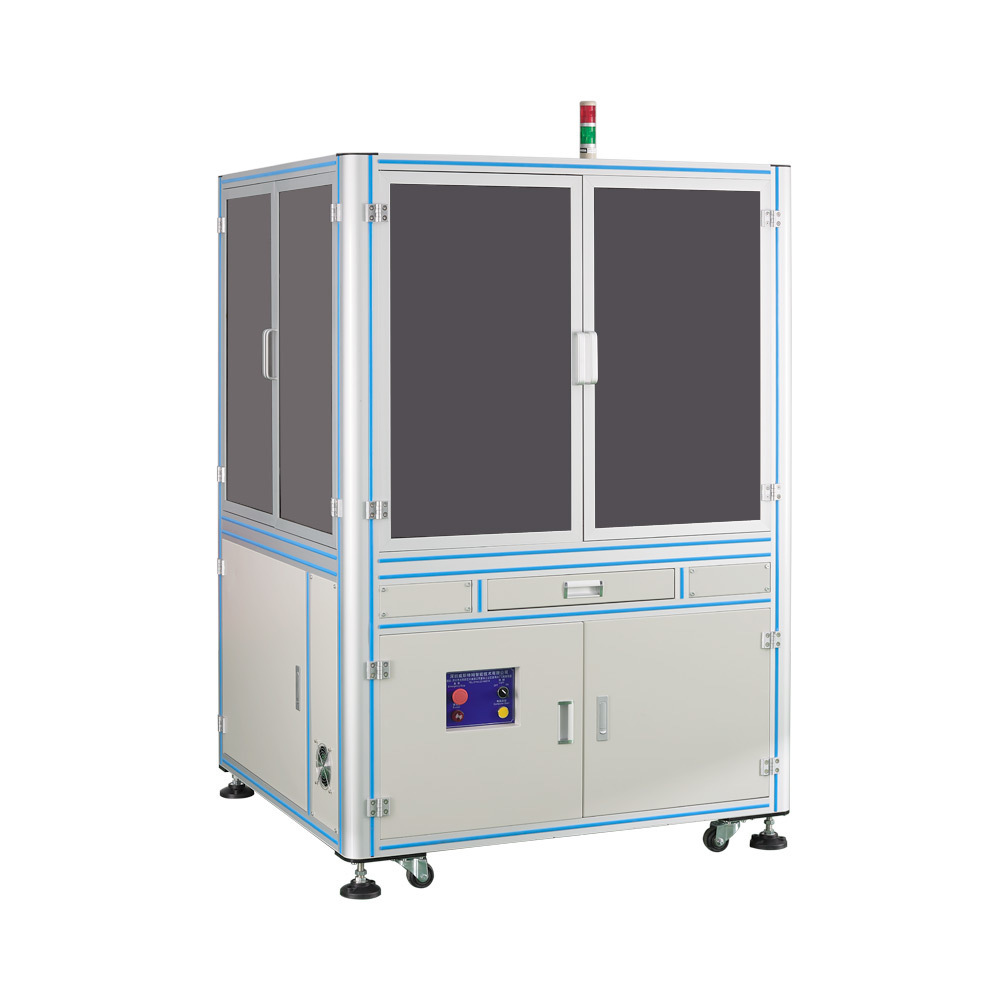

The manufacturing industry has continually evolved, driven by the need for efficiency and precision. At the forefront of this evolution are **CCD360 Degree Rotating Screening Machines**, which represent a significant advancement in material processing technology. These machines are designed to optimize the separation of varying materials, making them indispensable in sectors such as mining, recycling, and construction.

The CCD360 machine's rotating capabilities allow for a comprehensive approach to screening, ensuring that materials are sorted effectively and efficiently. This article will delve into the mechanics, advantages, and implementation methods of these cutting-edge machines, providing readers with a comprehensive understanding of their role in maximizing operational efficiency.

2. Understanding Screening Technology

Screening technology serves as the backbone of many industrial processes. It enables the separation of different materials based on size, shape, and density. The **CCD360 Degree Rotating Screening Machine** enhances traditional screening processes by incorporating rotational movement, which increases the efficiency of material sorting.

Traditional screening often suffers from limitations, such as inadequate separation efficiency and high operational costs. In contrast, the CCD360 technology utilizes an innovative design that mitigates these shortcomings. The unique rotating mechanism allows for continuous and uniform movement, which aids in the effective classification of materials.

3. Benefits of CCD360 Degree Rotating Screening Technology

The benefits of integrating CCD360 Degree Rotating Screening Machines into manufacturing processes are manifold. Here are three key advantages:

3.1 Enhanced Efficiency

The primary advantage of the CCD360 machine is its enhanced efficiency in material processing. The continuous rotation facilitates faster screening times, allowing for higher throughput. This efficiency translates to reduced operational delays and improved production schedules, making it an invaluable asset in any manufacturing setup.

3.2 Improved Material Separation

Another significant benefit is the improved precision in material separation. The CCD360 technology uses a combination of gravitational and centrifugal forces, which work together to ensure that materials are sorted with a high degree of accuracy. This capability minimizes the chances of contamination and ensures that only the desired products reach the next stage of processing.

3.3 Reduced Operating Costs

Integrating CCD360 machines not only boosts efficiency but also leads to lower operating costs. The reduced energy consumption and minimized wear and tear on machinery contribute to overall operational savings. Moreover, the increased uptime and fewer maintenance requirements make these machines a cost-effective choice for long-term investment.

4. Technical Specifications of CCD360 Machines

Understanding the technical specifications of CCD360 Degree Rotating Screening Machines is crucial for assessing their suitability for specific applications. Key specifications include:

- **Screening Area Size**: The total area available for screening, which directly impacts throughput capacity.

- **Rotational Speed**: The speed at which the machine operates, affecting the efficiency of material separation.

- **Material Compatibility**: The types of materials that can be processed, including their density and size.

- **Power Requirements**: The energy consumption required for optimal functioning, which influences operating costs.

- **Weight and Dimensions**: Important for spatial considerations in manufacturing facilities.

Each of these specifications plays a crucial role in determining how well the machine will perform in a given environment.

5. Operational Principles of CCD360 Screening Machines

The operational principles of the CCD360 machines are grounded in innovative engineering. The machines utilize a rotating screen that performs a dual function: screening and sorting. As materials enter the mechanism, the rotation allows them to move through different sizing stages. The unique design ensures that larger particles are separated effectively, while finer materials pass through the mesh.

The continuous motion not only enhances the separation process but also reduces the likelihood of material clogging, resulting in uninterrupted operation. This operational efficiency is critical in high-demand settings, where time and accuracy are of the essence.

6. Implementation Strategies for CCD360 Machines

Integrating CCD360 Degree Rotating Screening Machines into existing operations requires strategic planning. Here are several implementation strategies to consider:

- **Conduct a Needs Assessment**: Evaluate current processing methods to identify inefficiencies and determine the specific needs that the CCD360 machine can address.

- **Pilot Testing**: Before full implementation, conduct pilot testing with the machine to gauge performance and make necessary adjustments.

- **Training Personnel**: Ensure that operators and maintenance staff are trained adequately to handle the new technology, maximizing its potential.

- **Monitor Performance**: After implementation, continuously monitor the machine’s performance to identify areas for improvement and ensure optimal operation.

By following these strategies, companies can ensure a smooth transition to using CCD360 machines while maximizing their benefits.

7. Maintenance Tips for Longevity

Maintaining CCD360 Degree Rotating Screening Machines is essential for maximizing their lifespan and performance. Here are critical maintenance tips:

- **Regular Cleaning**: Schedule routine cleaning to prevent material buildup, which can affect screening performance.

- **Lubrication**: Ensure moving parts are adequately lubricated to reduce friction and wear.

- **Inspect Components**: Regularly inspect critical components for signs of wear and tear, replacing them as necessary to avoid operational disruptions.

- **Monitor Settings**: Keep an eye on machine settings and adjust them based on the materials being processed for optimal performance.

Adhering to these maintenance practices will help prolong the machine's life and ensure consistent operational efficiency.

8. Future Trends in Screening Technology

The future of screening technology is ripe with innovation. As industries turn toward automation and smart manufacturing solutions, CCD360 machines are poised to evolve further. Trends to look out for include:

- **Integration with IoT**: Internet of Things (IoT) technology will enable real-time monitoring and data analysis, enhancing machine performance and predictive maintenance.

- **Sustainability**: As industries push for sustainability, machines will be designed to operate on less energy while maximizing output, aligning with global sustainability goals.

- **Advanced Materials**: The development of better screening materials will improve efficiency and reduce wear, enhancing machine longevity.

These trends signify a shift towards smarter, more efficient manufacturing processes, reinforcing the ongoing importance of technologies like the CCD360.

9. Conclusion

In summary, **CCD360 Degree Rotating Screening Machines** are transforming the landscape of material processing in various industries. Their ability to maximize efficiency, improve material separation, and reduce operating costs makes them a vital addition to any manufacturing environment. As technology continues to evolve, the integration of such advanced machinery will play a crucial role in driving productivity and sustainability in the manufacturing sector.

10. Frequently Asked Questions (FAQs)

1. What materials can be processed using CCD360 Degree Rotating Screening Machines?

CCD360 machines are versatile and can handle various materials, including aggregates, metals, plastics, and more, depending on the specific configuration and mesh size.

2. How do CCD360 machines compare to traditional screening equipment?

Compared to traditional equipment, CCD360 machines offer enhanced screening efficiency, improved material separation, and lower operational costs due to their innovative design.

3. What is the typical lifespan of a CCD360 Degree Rotating Screening Machine?

With proper maintenance, these machines can last several years, often exceeding a decade of operational life, contingent on usage and care.

4. Can CCD360 machines be automated?

Yes, many CCD360 machines can be integrated with automation systems, allowing for remote monitoring and control, further enhancing operational efficiency.

5. What are the key maintenance practices for CCD360 machines?

Routine cleaning, regular lubrication, inspection of components, and monitoring settings are essential maintenance practices that help ensure longevity and optimal performance.

By understanding the capabilities and benefits of CCD360 Degree Rotating Screening Machines, manufacturers can make informed decisions that enhance their operational efficiency and productivity.

Related News