Maximizing Quality Assurance with AOI Visual Inspection in Optical Instruments

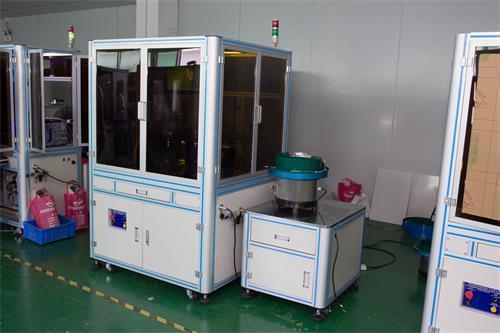

Automated Optical Inspection (AOI) is a crucial process in the quality assurance spectrum of optical instruments, especially when it comes to components like lenses and optical devices. The primary function of AOI visual inspection is to detect defects and ensure that products meet stringent quality standards before they are shipped to customers. With the increasing complexity of optical systems, the need for accurate and efficient inspection methods has never been more critical.

One of the most significant advantages of AOI visual inspection is its ability to automate the detection of defects. Traditional inspection methods can be time-consuming and rely heavily on human judgment, which may lead to inconsistencies. In contrast, AOI systems utilize advanced imaging technology and sophisticated algorithms to analyze products rapidly and accurately. This not only streamlines the inspection process but also significantly reduces the risk of human error, thereby enhancing the reliability of the inspection results.

In addition to speed and accuracy, AOI visual inspection offers a comprehensive approach to quality assurance. It can identify a wide range of defects, including surface scratches, alignment issues, and optical aberrations that may not be visible to the naked eye. By integrating AOI into the production workflow, manufacturers can ensure that any defects are identified and rectified early in the process, ultimately saving time and reducing costs associated with rework and returns.

For professionals looking to implement AOI visual inspection in their operations, it is essential to select the right system that aligns with their specific needs. Key considerations include resolution, speed, and the capability to handle various optical components. Additionally, investing in ongoing training for staff to operate and maintain AOI systems effectively can lead to improved inspection outcomes and overall product quality.

Moreover, the implementation of AOI visual inspection can be complemented by other quality management practices such as Six Sigma and Lean Manufacturing. These methodologies can further enhance the effectiveness of AOI by fostering a culture of continuous improvement and waste reduction.

In conclusion, AOI visual inspection represents a transformative approach for ensuring quality in the optical instruments industry. By embracing this technology, professionals can enhance their production processes, reduce defects, and ultimately deliver superior products to their customers. As the industry continues to evolve, adopting innovative inspection techniques like AOI will be key to maintaining a competitive edge in the market.

One of the most significant advantages of AOI visual inspection is its ability to automate the detection of defects. Traditional inspection methods can be time-consuming and rely heavily on human judgment, which may lead to inconsistencies. In contrast, AOI systems utilize advanced imaging technology and sophisticated algorithms to analyze products rapidly and accurately. This not only streamlines the inspection process but also significantly reduces the risk of human error, thereby enhancing the reliability of the inspection results.

In addition to speed and accuracy, AOI visual inspection offers a comprehensive approach to quality assurance. It can identify a wide range of defects, including surface scratches, alignment issues, and optical aberrations that may not be visible to the naked eye. By integrating AOI into the production workflow, manufacturers can ensure that any defects are identified and rectified early in the process, ultimately saving time and reducing costs associated with rework and returns.

For professionals looking to implement AOI visual inspection in their operations, it is essential to select the right system that aligns with their specific needs. Key considerations include resolution, speed, and the capability to handle various optical components. Additionally, investing in ongoing training for staff to operate and maintain AOI systems effectively can lead to improved inspection outcomes and overall product quality.

Moreover, the implementation of AOI visual inspection can be complemented by other quality management practices such as Six Sigma and Lean Manufacturing. These methodologies can further enhance the effectiveness of AOI by fostering a culture of continuous improvement and waste reduction.

In conclusion, AOI visual inspection represents a transformative approach for ensuring quality in the optical instruments industry. By embracing this technology, professionals can enhance their production processes, reduce defects, and ultimately deliver superior products to their customers. As the industry continues to evolve, adopting innovative inspection techniques like AOI will be key to maintaining a competitive edge in the market.

Related News