The Intersection of AOI Visual Inspection and Sustainable Manufacturing Practices

The Intersection of AOI Visual Inspection and Sustainable Manufacturing Practices

Introduction to AOI and Sustainable Manufacturing

In today’s rapidly evolving industrial landscape, the quest for sustainability is at the forefront of manufacturing practices. **Automated Optical Inspection (AOI)** represents a significant technological advancement that not only enhances product quality but also aligns seamlessly with the principles of sustainable manufacturing. This article delves into how AOI visual inspection techniques are transforming the manufacturing sector by promoting eco-friendly practices, reducing waste, and improving operational efficiencies.

Understanding Automated Optical Inspection (AOI)

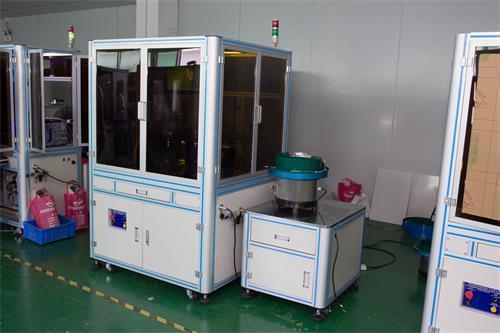

AOI is a sophisticated visual inspection process that utilizes advanced imaging technology to evaluate products for defects and inconsistencies. The technology employs high-resolution cameras and sophisticated software algorithms to analyze images of components, allowing manufacturers to quickly identify and rectify issues.

The Evolution of AOI Technology

The journey of AOI technology has seen remarkable advancements over the years. From its inception in the late 20th century to the present day, AOI has evolved to incorporate artificial intelligence (AI) and machine learning (ML) capabilities. These enhancements enable more precise inspections, faster processing times, and the ability to learn from past inspections, thereby continuously improving the quality assurance process.

How AOI Works

The AOI process typically includes several key steps:

1. **Image Capture**: High-resolution cameras capture images of the manufactured components.

2. **Image Processing**: Advanced algorithms analyze the captured images for any defects or deviations from the standard.

3. **Decision Making**: The system determines whether the component meets quality standards based on predefined criteria.

4. **Feedback Loop**: Information about detected defects is fed back into the production process for immediate corrective action.

Sustainable Manufacturing Practices: An Overview

Sustainable manufacturing encompasses various strategies aimed at producing goods in a manner that minimizes negative environmental impacts while conserving energy and natural resources. Key aspects include waste reduction, energy efficiency, and the use of renewable resources.

The Importance of Sustainable Manufacturing

As global awareness of environmental issues rises, businesses increasingly recognize the importance of integrating sustainability into their manufacturing processes. Sustainable practices not only enhance a company’s reputation and compliance with regulations but also lead to cost savings, improved efficiency, and a competitive edge in the marketplace.

Integrating AOI with Sustainable Manufacturing

The integration of AOI technology into sustainable manufacturing practices offers numerous benefits that can help organizations achieve their sustainability goals.

Enhancing Quality Control

One of the primary benefits of AOI is its ability to improve quality control processes. By enabling real-time inspections, AOI significantly reduces the likelihood of defective products reaching the market, which in turn minimizes waste and resource consumption. Manufacturers can ensure that only the highest quality components are produced, leading to reduced returns and rework.

Reducing Material Waste

AOI technology contributes to waste reduction by identifying defects early in the production process. By catching errors before components move further along the production line, manufacturers can prevent the use of excess materials and minimize the disposal of defective products. This not only leads to cost savings but also supports environmental sustainability.

Energy Efficiency and Operational Improvement

The automation provided by AOI systems increases operational efficiency, allowing manufacturers to streamline their processes. This efficiency translates to reduced energy consumption, as machines operate optimally with minimal downtime. Furthermore, by improving the overall production process, manufacturers can achieve higher output levels without a corresponding increase in energy use.

Supporting Circular Economy Initiatives

The principles of a circular economy focus on reusing and recycling materials to create a closed-loop system. AOI aids in identifying components that can be refurbished or reused, supporting manufacturers in their efforts to reduce waste and promote the recycling of materials. This alignment with circular economy initiatives enhances a company’s sustainability profile.

The Role of Technology in Sustainable Manufacturing

Advancements in technology play a crucial role in the evolution of sustainable manufacturing. AOI is just one of many technologies that contribute to this paradigm shift.

Innovative Technologies Complementing AOI

Several other technologies complement AOI in promoting sustainable manufacturing:

- **Internet of Things (IoT)**: IoT devices collect and analyze data from production processes, enabling manufacturers to optimize operations and reduce waste.

- **Artificial Intelligence (AI)**: AI algorithms can predict maintenance needs and optimize resource use, further enhancing sustainability efforts.

- **Robotics and Automation**: Robotics streamline production processes, reduce labor costs, and minimize human errors, leading to more efficient manufacturing.

Challenges and Considerations in Implementing AOI

While the benefits of AOI in sustainable manufacturing are significant, there are challenges that organizations must consider when implementing this technology.

Initial Investment Costs

The upfront costs associated with AOI systems can be substantial. However, it is essential for manufacturers to view these expenses as an investment in the future. The long-term benefits, including reduced waste and improved efficiency, often outweigh the initial financial outlay.

Need for Employee Training

Implementing AOI technology requires proper training for employees to ensure they can operate the systems effectively. Manufacturers must invest in training programs to equip their workforce with the necessary skills to leverage AOI fully.

Integration with Existing Systems

Integrating AOI with existing production processes may pose challenges. Manufacturers must carefully plan the implementation to ensure a smooth transition and avoid disruptions in production.

Case Studies: Successful Implementation of AOI in Sustainable Manufacturing

Examining real-world examples provides valuable insights into how AOI has effectively supported sustainable manufacturing practices.

Case Study 1: Electronics Manufacturer

An electronics manufacturer implemented AOI technology to enhance its quality control processes. As a result, the company reported a 30% reduction in defects and a 25% decrease in material waste. The integration of AOI not only improved product quality but also helped the company achieve its sustainability targets.

Case Study 2: Automotive Supplier

An automotive parts supplier adopted AOI to streamline its production process. By improving inspection times and reducing the reliance on manual inspections, the company increased its production efficiency by 40%. This enhancement allowed them to reduce energy consumption and align their operations with sustainable manufacturing principles.

Future Trends in AOI and Sustainable Manufacturing

As technology continues to advance, the future of AOI in sustainable manufacturing looks promising. Emerging trends include:

Increased Use of AI and Machine Learning

The integration of AI and machine learning into AOI systems will enable more sophisticated inspections and predictive maintenance capabilities. This advancement will further enhance sustainable practices by optimizing resource use and reducing downtime.

Collaboration Across the Supply Chain

Sustainable manufacturing will increasingly depend on collaboration across the entire supply chain. AOI technology can facilitate better communication and data sharing, enabling companies to work together towards common sustainability goals.

Conclusion

The intersection of **Automated Optical Inspection (AOI)** and **sustainable manufacturing practices** presents a powerful opportunity for organizations seeking to enhance product quality while minimizing their environmental impact. By embracing AOI technology, manufacturers can reduce waste, improve operational efficiency, and support circular economy initiatives. As the industry continues to evolve, the integration of innovative technologies will play a crucial role in shaping the future of sustainable manufacturing.

Frequently Asked Questions (FAQs)

1. What is AOI technology?

AOI, or Automated Optical Inspection, is a technology used in manufacturing to automatically inspect products for defects using high-resolution cameras and software algorithms.

2. How does AOI contribute to sustainable manufacturing?

AOI contributes to sustainable manufacturing by improving product quality, reducing waste, increasing operational efficiency, and supporting circular economy initiatives.

3. What are the benefits of implementing AOI in manufacturing?

The benefits of implementing AOI include enhanced quality control, reduced material waste, improved energy efficiency, and streamlined production processes.

4. What challenges might manufacturers face when adopting AOI technology?

Challenges include initial investment costs, the need for employee training, and integration with existing systems.

5. Can AOI technology be integrated with other manufacturing technologies?

Yes, AOI can be integrated with technologies such as IoT, AI, and robotics to further enhance manufacturing processes and sustainability efforts.

Related News