Revolutionizing Rubber Recycling: The Role of Optical Sorting Machines

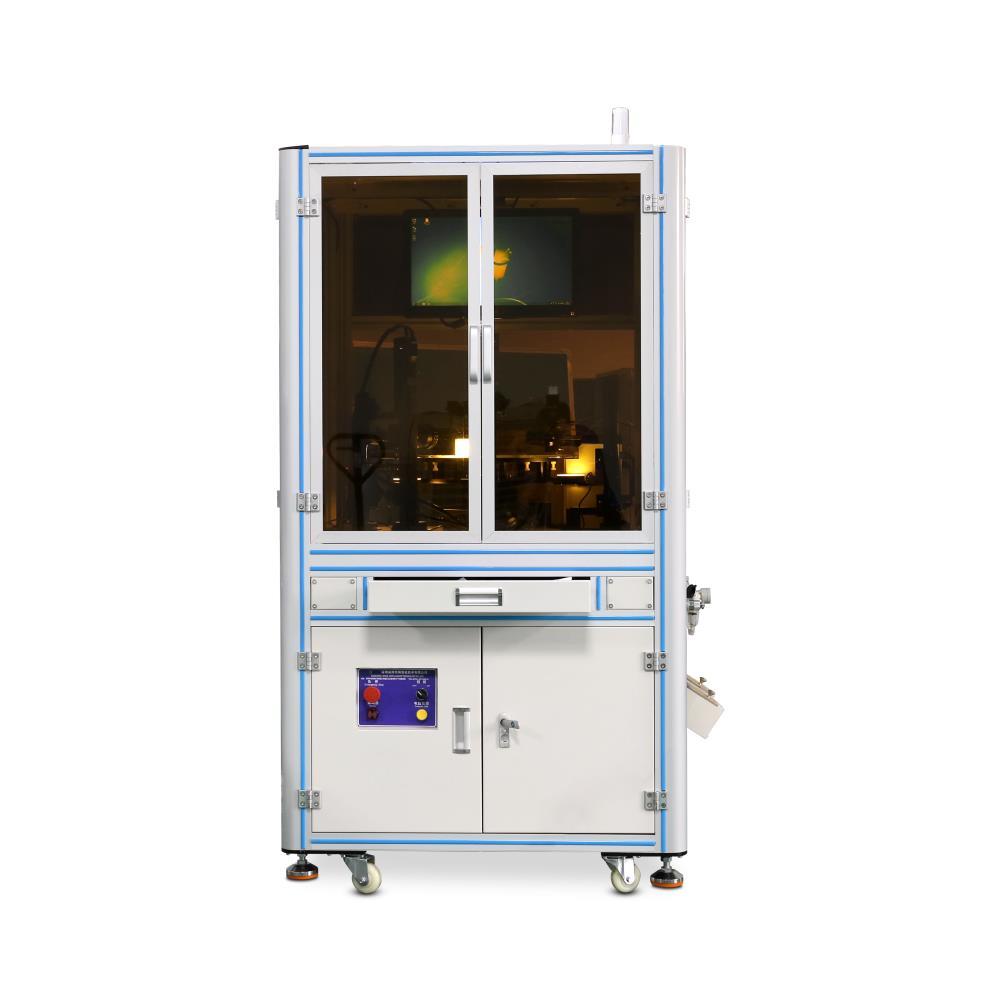

In the ever-evolving landscape of rubber manufacturing, the need for advanced sorting technology has become increasingly critical. Optical sorting machines for rubber products represent a significant innovation in the processing and recycling of rubber materials. These machines utilize sophisticated imaging technology to identify and sort rubber products based on color, shape, and other physical characteristics. This capability not only streamlines the recycling process but also enhances product quality and reduces waste.

One of the primary advantages of using optical sorting machines in rubber processing is their ability to improve sorting accuracy. Traditional sorting methods often rely on manual labor or basic mechanical systems, which can be prone to errors and inefficiencies. In contrast, optical sorting machines employ high-resolution cameras and advanced software algorithms to analyze and sort materials rapidly and accurately. This precision minimizes the risk of contamination and ensures that only high-quality rubber products are selected for further processing.

Additionally, optical sorting technology can significantly increase throughput in manufacturing processes. By automating the sorting procedure, these machines can handle larger volumes of rubber products in a shorter time frame. This efficiency not only accelerates production but also aligns with the industry's growing emphasis on sustainability and waste reduction. As manufacturers strive to meet higher environmental standards, the ability to recycle and reuse materials effectively has never been more crucial.

Moreover, optical sorting machines are versatile and can be customized to accommodate various types of rubber products. Whether dealing with tires, rubber scraps, or other rubber waste materials, these machines can be tailored to meet specific sorting requirements. This adaptability makes them valuable assets for businesses looking to enhance their operations and maintain a competitive edge in the market.

The integration of optical sorting machines into rubber processing facilities also supports data-driven decision-making. Many modern optical sorters are equipped with connectivity features that enable operators to collect and analyze sorting data in real time. This information can provide insights into production efficiency, product quality, and areas for improvement, allowing manufacturers to make informed adjustments to their processes.

In conclusion, optical sorting machines for rubber products are revolutionizing the recycling and manufacturing landscape by offering unparalleled accuracy, efficiency, and adaptability. As the demand for sustainable practices continues to rise, investing in such advanced sorting technologies is becoming increasingly essential for manufacturers in the rubber industry. Embracing these innovations not only enhances operational performance but also contributes to a more sustainable future for rubber processing.

One of the primary advantages of using optical sorting machines in rubber processing is their ability to improve sorting accuracy. Traditional sorting methods often rely on manual labor or basic mechanical systems, which can be prone to errors and inefficiencies. In contrast, optical sorting machines employ high-resolution cameras and advanced software algorithms to analyze and sort materials rapidly and accurately. This precision minimizes the risk of contamination and ensures that only high-quality rubber products are selected for further processing.

Additionally, optical sorting technology can significantly increase throughput in manufacturing processes. By automating the sorting procedure, these machines can handle larger volumes of rubber products in a shorter time frame. This efficiency not only accelerates production but also aligns with the industry's growing emphasis on sustainability and waste reduction. As manufacturers strive to meet higher environmental standards, the ability to recycle and reuse materials effectively has never been more crucial.

Moreover, optical sorting machines are versatile and can be customized to accommodate various types of rubber products. Whether dealing with tires, rubber scraps, or other rubber waste materials, these machines can be tailored to meet specific sorting requirements. This adaptability makes them valuable assets for businesses looking to enhance their operations and maintain a competitive edge in the market.

The integration of optical sorting machines into rubber processing facilities also supports data-driven decision-making. Many modern optical sorters are equipped with connectivity features that enable operators to collect and analyze sorting data in real time. This information can provide insights into production efficiency, product quality, and areas for improvement, allowing manufacturers to make informed adjustments to their processes.

In conclusion, optical sorting machines for rubber products are revolutionizing the recycling and manufacturing landscape by offering unparalleled accuracy, efficiency, and adaptability. As the demand for sustainable practices continues to rise, investing in such advanced sorting technologies is becoming increasingly essential for manufacturers in the rubber industry. Embracing these innovations not only enhances operational performance but also contributes to a more sustainable future for rubber processing.

Related News