Magnetic ring core optical sorting machine

Inspection items: ● Size detection ● Edge and corner chipping detection ● Slot hole foreign object detection ● Scratch, crack, sand hole, and knife mark detection ● Coating defect detection ● Bump and excess material detection

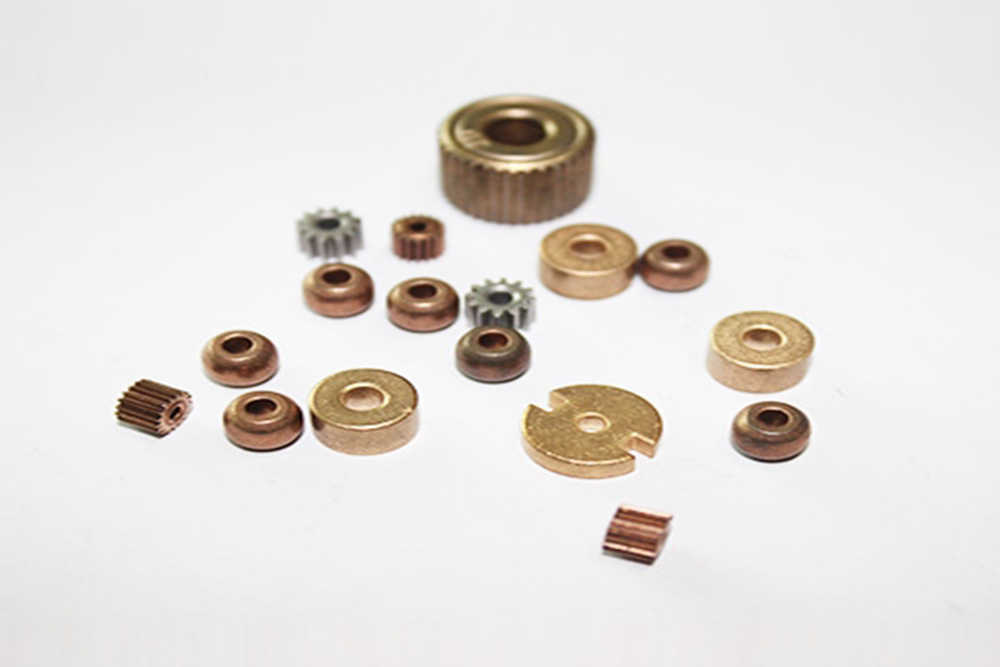

Product Application

Magnetic Material Optical Sorting Machine

Inspection items: ● Size inspection ● Corner chipping detection ● Slot hole plugging foreign object detection ● Scratches, cracks, trachoma, knife lines detection ● Defective plating detection ● Bump, multi-material detection

Product Application

O-ring optical sorting machine

Inspection items: ● Inner diameter, diameter detection ● Inner and outer circular edge material deficiency detection ● Surface defect detection ● Hole blockage detection ● Inner and outer circular burr detection

Product Application

Magnetic Tile Optical Sorting Machine

Inspection items: ● Crack and scratch detection ● Edge and corner chipping detection ● Bump and material excess detection ● Size detection ● Material shortage detection

Product Application

Oil Seal Optical Sorting Machine

Inspection items: ● Outer diameter and inner hole diameter detection ● 360-degree ring inspection for inner and outer wall defects ● Detection of missing material on inner and outer circular edges ● Surface defect detection ● Hole blockage detection ● Inner and outer circular burr detection ● Water inlet height detection ● Mixed material detection

Product Application

Tailored Automated Testing Solutions For Products in Different Industries

ABOUT WSDM

Dedicated to visual, laser, contact detection, and non-standard customized detection equipment

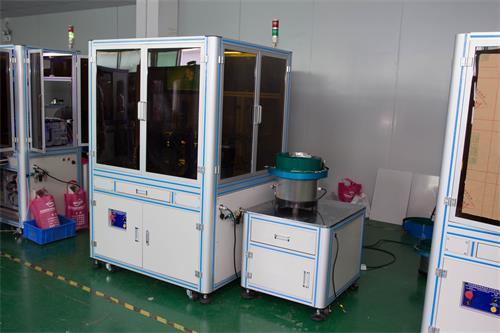

Shenzhen WSDM Intelligent Technology Co., Ltd. is a national high-tech enterprise dedicated to image visual inspection, integrating research and development, production, and sales. Adhering to 18 years of experience in image visual inspection, we have a senior R&D and management team in the image visual industry. With 18 years of development, we have accumulated rich practical experience. We can provide customized automated testing solutions for products in different industries. Our main products include CCD glass disc screening machines, CCD indexing disc screening machines, CCD 360 degree rotating screening machines, and fully automatic contact detection machines. The main industries involved include magnetic materials, POGOPIN probes, rubber products, connectors, electronic components, precision hardware, etc

Why Choose Us

Visual inspection equipment has the characteristics of fast detection speed, high detection accuracy, stable detection quality, and zero false detection rate, achieving full product inspection and eliminating customer complaints

01

Technical Advantages

Our company has been committed to machine vision research and development since 2003, with high dimensional detection accuracy and the ability to detect very subtle defects. The equipment is equipped with MES interface, which can connect to the enterprise information management system and monitor the detection status in real time. Provide intelligent and automated detection solutions for different products in the industry. Provide customers with high-quality and cost-effective products.

02

Wide Range of Applications

We provide customized intelligent testing equipment and services for industries such as automotive, military, fasteners, precision hardware, magnetic materials, rubber products, connectors, mobile phones, powder metallurgy, etc., including Fortune 500 companies such as Huawei, Apple, Samsung, LG, BMW, etc.

03

Fully Reinforced

Shenzhen Wisdom Intelligent Technology Co., Ltd. is a high-tech enterprise integrating scientific research, design, production, maintenance, and sales. It is committed to the research and development of precision optical visual inspection and has a professional team with more than ten years of inspection experience.

04

After-Sale Service

Provide a one-year free warranty service from the date of equipment delivery; During the warranty period, free replacement of machine parts is provided (excluding cases of human damage, loss, destruction, and force majeure); In addition, if equipment malfunctions during use, our company will not respond within 1 hour after receiving notification. We will send personnel to repair the equipment within 24 hours within the province and 36 hours outside the province to ensure its normal operation.