Unlocking the Future: The Magic of Ai Visual Inspection

What is Ai Visual Inspection?

Imagine a world where machines can spot defects faster than the human eye can blink. Welcome to the fascinating realm of Ai Visual Inspection! This technology is making waves in quality control across various industries, from manufacturing to healthcare. But how does it work? Buckle up, because we're about to dive into the nitty-gritty!

The Basics: How It All Comes Together

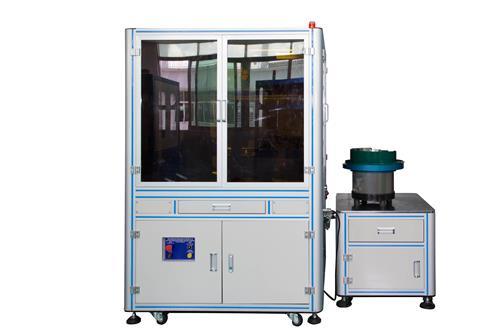

At its core, Ai Visual Inspection leverages artificial intelligence to analyze images and videos. Picture this: a high-resolution camera captures every nook and cranny of a product as it rolls off the assembly line. This footage is then processed by sophisticated algorithms that can identify defects, ensure compliance with standards, and even predict potential failures.

The Tech Behind the Magic

So, what’s the tech wizardry at play here? Well, it’s all about machine learning! These systems are trained on vast datasets, learning to distinguish between what’s normal and what’s not. Think of it as giving a machine a crash course in quality assurance—after enough practice, it becomes a pro.

Applications Galore!

Ai Visual Inspection is like that versatile tool in your toolbox—useful in a myriad of applications. In the automotive industry, for instance, it can spot tiny scratches or imperfections on vehicle surfaces. In pharmaceuticals, it ensures that packaging is sealed tight and labels are correctly placed. The possibilities are endless!

Why It Matters

Now, you might be wondering, "Why should I care?" Well, let’s break it down. First off, it drastically reduces human error. We all know that humans can be a bit absent-minded, right? With Ai Visual Inspection, you can bid farewell to missed defects. Additionally, this tech ramps up efficiency, speeds up processes, and ultimately saves costs. It’s a win-win!

Challenges on the Horizon

But hey, it’s not all sunshine and rainbows. There are challenges in implementing Ai Visual Inspection. For starters, the initial setup can be pricey, and integrating it into existing workflows often requires some heavy lifting. Moreover, the technology must be continuously updated to keep pace with new products and defects.

The Future Looks Bright

Despite these hurdles, the future of Ai Visual Inspection is looking brighter than a summer’s day. As technology continues to evolve, so will the capabilities of these systems. Imagine a day when every product is inspected with pinpoint accuracy, leading to higher quality and customer satisfaction. Now that’s something to get excited about!

Wrapping It Up

In the grand scheme of things, Ai Visual Inspection is not just a trend; it’s a revolution. By harnessing the power of artificial intelligence, industries can ensure that their products are not just good, but top-notch. So, whether you’re a tech enthusiast or a business owner, it’s clear that keeping an eye on this technology is essential. Who knows? It might just be the key to unlocking new heights of quality and efficiency in your operations.

Related News