Ensuring Excellence: The Importance of Precision Hardware Parts Inspection in Optical Instruments

Precision hardware parts inspection is an integral aspect of quality control in the manufacturing of optical instruments. The optical industry relies heavily on components that must meet stringent specifications in terms of dimensions, tolerances, and surface finishes. Any imperfections in these hardware parts can lead to significant performance issues, ranging from reduced image clarity to complete instrument failure. Therefore, understanding the processes involved in precision inspection is crucial for manufacturers and end-users alike.

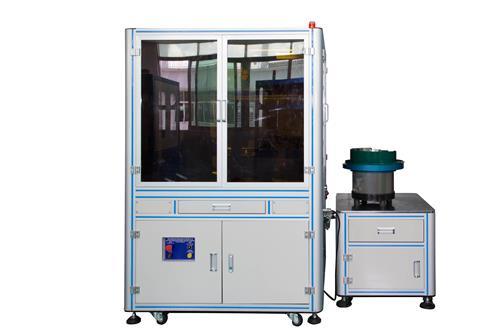

One of the primary goals of precision hardware parts inspection is to ensure that each component meets the designated specifications. This is typically achieved through a variety of measurement techniques, including optical measurement systems, coordinate measuring machines (CMM), and laser scanning. Each of these methods provides a means to assess the geometrical characteristics of the hardware parts with a high degree of accuracy.

Optical measurement systems, for instance, utilize light to analyze the dimensions of components. This non-contact method is particularly beneficial for delicate parts, as it eliminates the risk of damage that could occur with traditional contact measuring methods. By employing sophisticated optics and advanced software, manufacturers can detect even the smallest deviations from the specified tolerances.

In addition to dimensional accuracy, the surface quality of hardware parts is another critical factor that influences the overall functionality of optical instruments. Surface imperfections can scatter light, leading to distortions or loss of image quality. As a result, inspection processes often include assessments of surface roughness and finish, which can be evaluated using techniques such as profilometry or microscopy.

Furthermore, precision hardware parts inspection is not solely confined to the production phase. It extends into the maintenance and calibration of optical instruments. Regular inspections can identify wear and tear or misalignments that may develop over time, ensuring that instruments continue to operate at their peak performance levels.

The importance of precision inspection in the optical industry cannot be overstated. It not only enhances the quality and reliability of optical instruments but also fosters customer trust and satisfaction. By ensuring that every hardware part is thoroughly inspected, manufacturers can deliver products that meet the high expectations of their clients, ultimately leading to a competitive advantage in the marketplace.

In conclusion, precision hardware parts inspection is a vital process in the production and maintenance of optical instruments. With the right inspection techniques in place, manufacturers can safeguard the quality and performance of their products, ensuring that they meet the rigorous demands of the optical industry.

One of the primary goals of precision hardware parts inspection is to ensure that each component meets the designated specifications. This is typically achieved through a variety of measurement techniques, including optical measurement systems, coordinate measuring machines (CMM), and laser scanning. Each of these methods provides a means to assess the geometrical characteristics of the hardware parts with a high degree of accuracy.

Optical measurement systems, for instance, utilize light to analyze the dimensions of components. This non-contact method is particularly beneficial for delicate parts, as it eliminates the risk of damage that could occur with traditional contact measuring methods. By employing sophisticated optics and advanced software, manufacturers can detect even the smallest deviations from the specified tolerances.

In addition to dimensional accuracy, the surface quality of hardware parts is another critical factor that influences the overall functionality of optical instruments. Surface imperfections can scatter light, leading to distortions or loss of image quality. As a result, inspection processes often include assessments of surface roughness and finish, which can be evaluated using techniques such as profilometry or microscopy.

Furthermore, precision hardware parts inspection is not solely confined to the production phase. It extends into the maintenance and calibration of optical instruments. Regular inspections can identify wear and tear or misalignments that may develop over time, ensuring that instruments continue to operate at their peak performance levels.

The importance of precision inspection in the optical industry cannot be overstated. It not only enhances the quality and reliability of optical instruments but also fosters customer trust and satisfaction. By ensuring that every hardware part is thoroughly inspected, manufacturers can deliver products that meet the high expectations of their clients, ultimately leading to a competitive advantage in the marketplace.

In conclusion, precision hardware parts inspection is a vital process in the production and maintenance of optical instruments. With the right inspection techniques in place, manufacturers can safeguard the quality and performance of their products, ensuring that they meet the rigorous demands of the optical industry.

Related News