Exploring Aoi Automatic Optical Inspection: Applications and Innovations

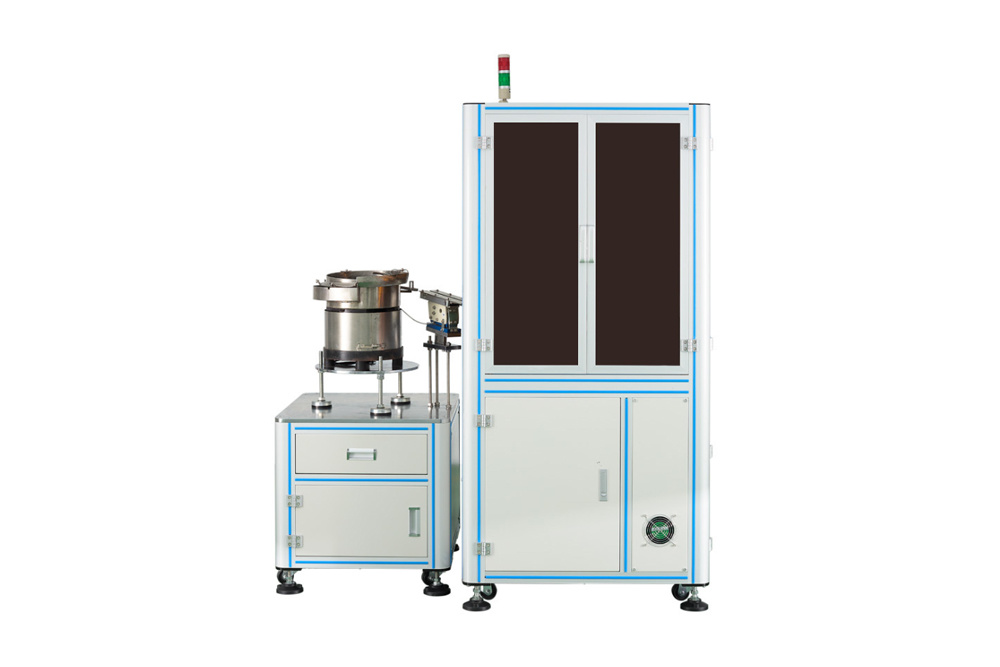

Introduction to Aoi Automatic Optical Inspection

In today’s fast-paced manufacturing landscape, quality control has become more critical than ever. Enter Aoi Automatic Optical Inspection—a game changer in ensuring product excellence. But what exactly is it, and how does it fit into various application scenarios? Buckle up, because we’re about to embark on an enlightening journey!

What is Aoi Automatic Optical Inspection?

Aoi Automatic Optical Inspection is a sophisticated technology that utilizes cameras and advanced algorithms to inspect products for defects. Imagine having an eagle-eyed inspector on the production line, tirelessly scanning every inch of a circuit board or a smartphone for flaws. This tech-driven approach not only enhances accuracy but also speeds up the inspection process, allowing manufacturers to deliver top-notch products with confidence.

Key Applications of Aoi Automatic Optical Inspection

Now, let’s dive into some real-world applications, shall we?

1. Electronics Manufacturing

In the electronics industry, Aoi Automatic Optical Inspection reigns supreme. From smartphones to complex circuit boards, the stakes are high. A tiny flaw can lead to significant failures. Using Aoi technology, manufacturers can swiftly detect soldering issues, misalignments, or missing components. Talk about peace of mind!

2. Automotive Sector

Ever wondered how modern vehicles maintain their high safety standards? Aoi Automatic Optical Inspection plays a crucial role here too! From inspecting sensors to ensuring precise fittings, this technology helps in guaranteeing that every part meets stringent quality requirements. It’s like having a built-in safety net for your ride!

3. Medical Device Manufacturing

When it comes to medical devices, there’s no room for error. Aoi Automatic Optical Inspection helps manufacturers verify the integrity of devices and components, ensuring they meet regulatory standards. After all, in healthcare, safety is paramount—and Aoi technology is a key player in keeping it that way.

Benefits of Adopting Aoi Automatic Optical Inspection

Okay, so we’ve seen where Aoi shines, but what about the benefits? Let’s break it down!

- Enhanced Accuracy: With advanced imaging techniques, Aoi systems can pinpoint defects that the human eye might miss.

- Increased Efficiency: Automation speeds up the inspection process, allowing for higher throughput without sacrificing quality.

- Cost Savings: By catching defects early, manufacturers can avoid costly rework and returns.

- Data Collection: Aoi systems often provide valuable data analytics, helping manufacturers refine their processes and improve product quality.

Challenges and Considerations

Of course, no technology is without its challenges. Implementing Aoi Automatic Optical Inspection requires upfront investment and a learning curve for staff. Additionally, the technology needs to be calibrated and maintained to ensure optimal performance. But hey, with great power comes great responsibility, right?

The Future of Aoi Automatic Optical Inspection

As we look to the horizon, it’s clear that Aoi Automatic Optical Inspection will only get more advanced. With the rise of AI and machine learning, we can expect even more sophisticated algorithms that can learn and adapt over time. Who knows, maybe one day, we’ll have systems that can self-correct based on inspection data. Exciting times ahead!

Conclusion

So there you have it—Aoi Automatic Optical Inspection is not just a fancy term; it’s a vital component of modern manufacturing. With its various applications and undeniable benefits, it’s no wonder that industries are increasingly turning to this technology. Whether it’s in electronics, automotive, or medical devices, the need for quality assurance has never been more critical. And as technology advances, the future looks bright for Aoi!

Related News