The Future of Manufacturing: AOI Automatic Optical Inspection Explained

The Future of Manufacturing: AOI Automatic Optical Inspection Explained

Table of Contents

- 1. Introduction to AOI in Manufacturing

- 2. What is Automatic Optical Inspection (AOI)?

- 3. How AOI Works: The Technology Behind the Magic

- 4. The Benefits of Using AOI in Manufacturing

- 5. Applications of AOI in Various Industries

- 6. Future Trends in AOI Technology

- 7. Challenges in Implementing AOI

- 8. Frequently Asked Questions About AOI

- 9. Conclusion: The Impact of AOI on the Future of Manufacturing

1. Introduction to AOI in Manufacturing

As the manufacturing landscape evolves, so too do the technologies that drive efficiency and quality. One such innovation is **Automatic Optical Inspection (AOI)**, a critical component in modern manufacturing processes. AOI employs sophisticated imaging technology to detect defects in products, ensuring that quality control is maintained throughout the production cycle. With the rising complexities of modern products and the ever-increasing demand for higher quality, AOI has become indispensable for manufacturers looking to stay competitive.

2. What is Automatic Optical Inspection (AOI)?

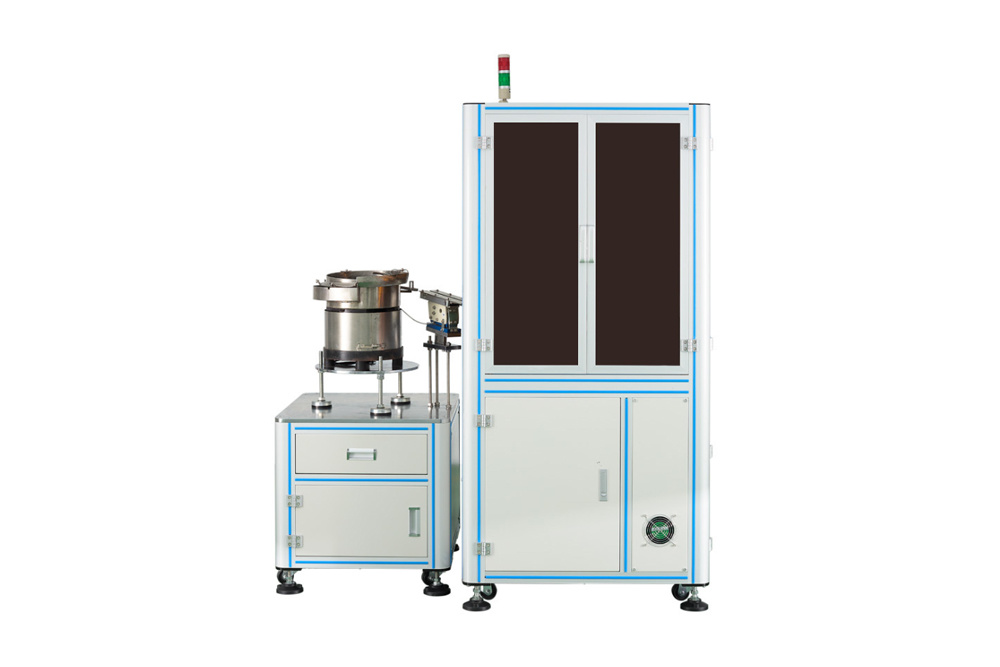

Automatic Optical Inspection is a non-contact testing method that utilizes advanced imaging technology to examine printed circuit boards (PCBs) and other components for defects. AOI systems are equipped with high-resolution cameras and sophisticated software that can analyze images at remarkable speeds. The primary goal of AOI is to identify defects early in the manufacturing process, thus minimizing waste and reducing costs associated with defective products.

Key Components of AOI Systems

- **High-Resolution Cameras:** Capture detailed images of components and PCBs.

- **Illumination Systems:** Use various light sources to enhance image quality for accurate defect detection.

- **Software Algorithms:** Analyze images to identify discrepancies between the actual product and the design specifications.

3. How AOI Works: The Technology Behind the Magic

Understanding the mechanics of AOI can help manufacturers make informed decisions about implementing this technology. AOI operates through several steps:

Image Acquisition

The process begins with the AOI system capturing images of the product using high-resolution cameras. Depending on the illumination setup, various angles and lighting conditions are used to obtain the best possible image.

Image Processing

Once the images are acquired, the software algorithms compare them to pre-defined standards. This comparison allows the system to detect defects, such as missing components, misalignments, and soldering issues.

Defect Classification

After identifying potential defects, the system categorizes them based on severity. This classification aids operators in prioritizing which issues need immediate attention and which can be addressed later.

Feedback Loop

AOI systems often include a feedback loop that provides information back to the manufacturing process. This real-time data allows for immediate adjustments to enhance quality control.

4. The Benefits of Using AOI in Manufacturing

Implementing AOI systems comes with a myriad of advantages that can streamline production and enhance overall quality.

Increased Inspection Speed

AOI systems can inspect products much faster than human operators, significantly increasing throughput rates and enabling manufacturers to meet high demand.

Enhanced Detection Accuracy

With sophisticated imaging and algorithmic analysis, AOI systems surpass human capabilities in identifying microscopic defects, thereby enhancing product reliability.

Cost Reduction

By identifying defects early, AOI helps minimize waste and reduce costs associated with rework and scrap, ultimately improving the bottom line.

Improved Consistency

AOI ensures that each product is inspected against the same criteria, leading to greater consistency in quality across production runs.

5. Applications of AOI in Various Industries

AOI is not limited to one sector; its applications are widespread across multiple industries, including:

Electronics Manufacturing

In the electronics sector, AOI is primarily used for inspecting PCBs, ensuring that all components are properly placed and soldered.

Automotive Industry

Manufacturers in the automotive industry rely on AOI for inspecting complex assemblies and components, ensuring they meet safety and quality standards.

Medical Device Manufacturing

The medical device sector uses AOI to verify the integrity of devices where precision is crucial, helping to maintain compliance with regulatory standards.

Consumer Goods

In the production of consumer goods, AOI systems help detect defects that could lead to product recalls, thus safeguarding brand reputation.

6. Future Trends in AOI Technology

As technology continues to advance, so will AOI systems. Several trends are emerging that will shape the future of AOI in manufacturing.

Integration with AI and Machine Learning

The incorporation of artificial intelligence and machine learning algorithms will enhance AOI capabilities, enabling predictive maintenance and improved defect detection.

Increased Automation

Future AOI systems will likely be more automated, reducing the need for human intervention and further streamlining manufacturing processes.

Enhanced Data Analytics

Advanced data analytics will provide manufacturers with deeper insights into production processes, enabling them to make data-driven decisions for continuous improvement.

7. Challenges in Implementing AOI

While the advantages of AOI are substantial, manufacturers must also consider the challenges that may arise during implementation.

High Initial Investment

The cost of implementing AOI systems can be significant, which may deter some manufacturers from adopting this technology.

Technical Complexity

Setting up and maintaining AOI systems requires specialized knowledge and skills, which can pose a challenge for some organizations.

Integration with Existing Systems

Seamlessly integrating AOI technology with existing manufacturing systems can be complex and may require additional resources.

8. Frequently Asked Questions About AOI

What types of defects can AOI detect?

AOI can identify a wide range of defects, including missing components, misalignments, soldering issues, and surface defects.

How does AOI improve quality control?

By identifying defects early in the manufacturing process, AOI helps maintain high-quality standards and reduces the risk of defective products reaching consumers.

Is AOI suitable for small-scale manufacturing?

Yes, although the initial investment may be higher, AOI can be beneficial for small-scale manufacturers by improving efficiency and reducing waste.

Can AOI systems be customized?

Many AOI systems offer customization options to cater to specific manufacturing needs and product types.

What is the typical ROI for implementing AOI?

The return on investment (ROI) varies by industry and application, but many manufacturers report significant cost savings and improved efficiencies.

9. Conclusion: The Impact of AOI on the Future of Manufacturing

Automatic Optical Inspection (AOI) is not just a technological advancement; it is a pivotal change that stands to redefine manufacturing processes. By offering rapid, accurate, and reliable inspection capabilities, AOI systems enhance product quality and operational efficiency. As we look to the future, the integration of AI, increased automation, and enhanced data analytics will only further solidify AOI's role as a cornerstone of modern manufacturing. Embracing this technology will allow manufacturers to meet the challenges of today and excel in an increasingly competitive landscape.

Related News