Revolutionizing Rubber Recycling: The Role of Optical Sorting Machines

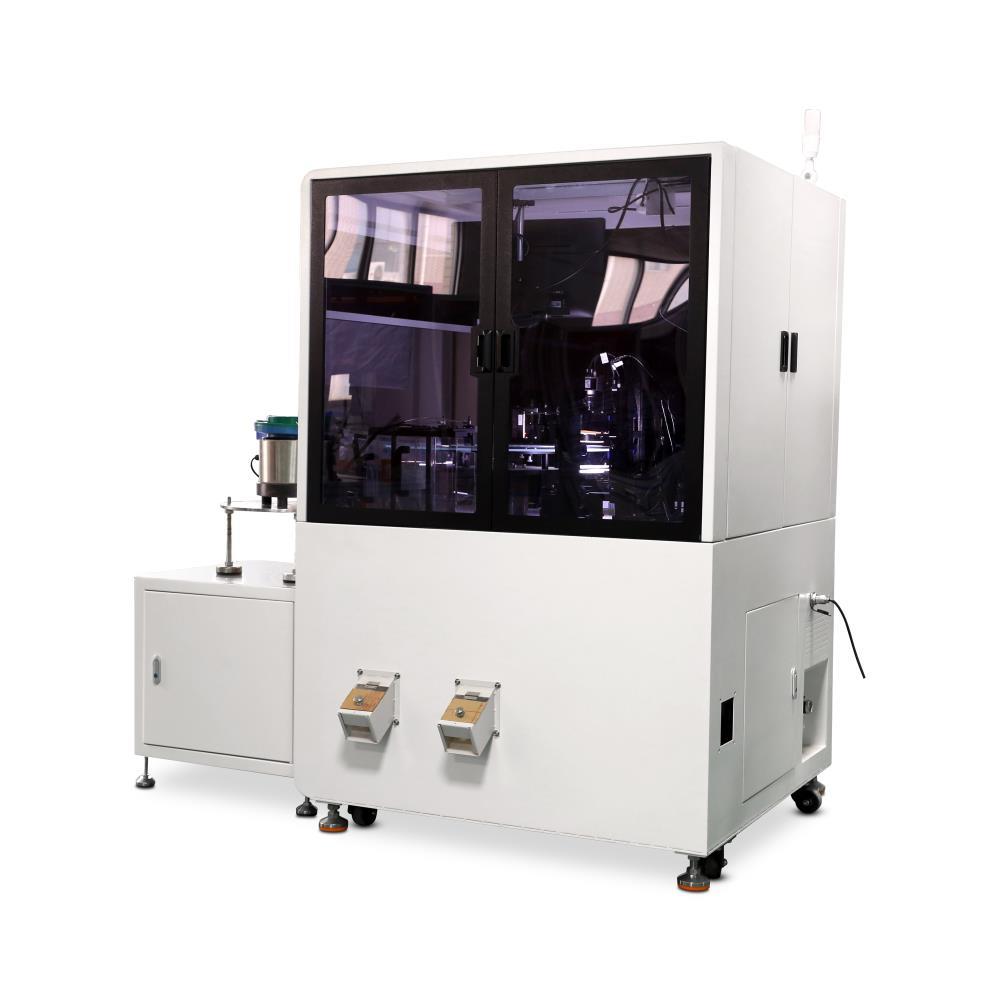

In the realm of manufacturing and processing machinery, particularly in the field of crushing and sorting equipment, the role of optical sorting machines has gained considerable attention, especially concerning rubber products. Optical sorting machines leverage advanced imaging technologies to identify and separate materials based on color, size, and shape, which is crucial in the recycling of rubber products.

Rubber recycling is a complex process, often hampered by the presence of contaminants that can degrade the quality of the final product. Traditional sorting methods, such as manual sorting or mechanical screening, may not effectively remove these contaminants, leading to lower quality recycled materials. This is where optical sorting machines come into play, providing a more efficient and effective means of sorting rubber materials.

The primary advantage of optical sorting machines lies in their ability to process materials at high speed with precision. These machines utilize cameras and sensors to capture images of rubber products, enabling them to differentiate between various materials with remarkable accuracy. This capability not only improves the purity of recycled rubber but also enhances the overall efficiency of the recycling process. By effectively eliminating contaminants, manufacturers can ensure that the recycled rubber meets industry standards, making it suitable for various applications.

Moreover, optical sorting machines contribute to sustainability efforts within the rubber industry. As the demand for eco-friendly products rises, the need for effective recycling methods has never been more pressing. By streamlining the sorting process, these machines support manufacturers in reducing waste and minimizing the environmental impact of rubber production. This aligns with global efforts to promote circular economies, where materials are continuously reused and recycled.

In addition to their environmental benefits, optical sorting machines have a direct impact on the cost-effectiveness of rubber recycling operations. By reducing the need for manual labor and minimizing errors in sorting, these machines can lower operational costs and increase profitability for manufacturers. The ability to quickly process large volumes of rubber waste further enhances their economic viability, making them an indispensable tool in modern recycling facilities.

In conclusion, optical sorting machines for rubber products represent a significant advancement in recycling technology. Their ability to enhance sorting efficiency, improve material purity, and support sustainability initiatives makes them a valuable asset for manufacturers in the rubber industry. As the demand for recycled materials continues to grow, the integration of these advanced sorting solutions will play a crucial role in shaping the future of rubber recycling and contributing to a more sustainable manufacturing landscape.

Rubber recycling is a complex process, often hampered by the presence of contaminants that can degrade the quality of the final product. Traditional sorting methods, such as manual sorting or mechanical screening, may not effectively remove these contaminants, leading to lower quality recycled materials. This is where optical sorting machines come into play, providing a more efficient and effective means of sorting rubber materials.

The primary advantage of optical sorting machines lies in their ability to process materials at high speed with precision. These machines utilize cameras and sensors to capture images of rubber products, enabling them to differentiate between various materials with remarkable accuracy. This capability not only improves the purity of recycled rubber but also enhances the overall efficiency of the recycling process. By effectively eliminating contaminants, manufacturers can ensure that the recycled rubber meets industry standards, making it suitable for various applications.

Moreover, optical sorting machines contribute to sustainability efforts within the rubber industry. As the demand for eco-friendly products rises, the need for effective recycling methods has never been more pressing. By streamlining the sorting process, these machines support manufacturers in reducing waste and minimizing the environmental impact of rubber production. This aligns with global efforts to promote circular economies, where materials are continuously reused and recycled.

In addition to their environmental benefits, optical sorting machines have a direct impact on the cost-effectiveness of rubber recycling operations. By reducing the need for manual labor and minimizing errors in sorting, these machines can lower operational costs and increase profitability for manufacturers. The ability to quickly process large volumes of rubber waste further enhances their economic viability, making them an indispensable tool in modern recycling facilities.

In conclusion, optical sorting machines for rubber products represent a significant advancement in recycling technology. Their ability to enhance sorting efficiency, improve material purity, and support sustainability initiatives makes them a valuable asset for manufacturers in the rubber industry. As the demand for recycled materials continues to grow, the integration of these advanced sorting solutions will play a crucial role in shaping the future of rubber recycling and contributing to a more sustainable manufacturing landscape.

Related News